THE ULTIMATE TOOL

FOR MANUFACTURING

COMPOSITES

Designed and developed to improve the way reinforced composites are manufactured nowadays, the Tervia Hub is a unique IoT system, capable to automatically detect the position of leaks in a tool. Also measures resin cure and sends alarms when part is fully cured. Records atmospheric pressure, vacuum, temperature and fiber humidity to improve your part processing.

LEAK DETECTION

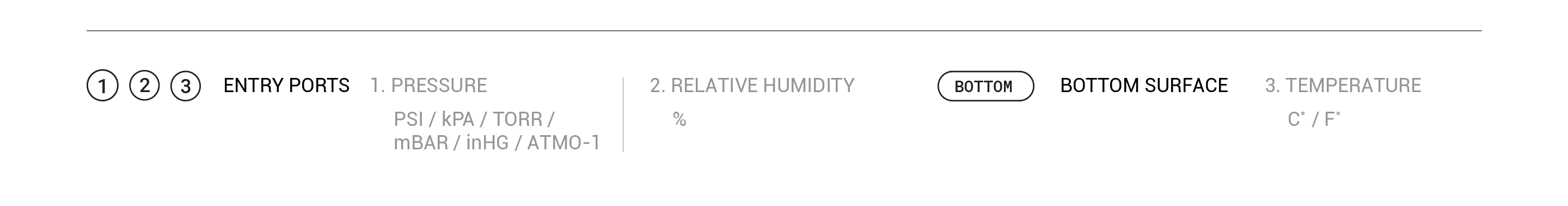

By connecting the three hoses to your tool, Tervia Hub is capable to perform the following tasks:

- Run automatic leak rate tests,

- Detect and locate air leaks on vacuum bagging tools,

- Display and record manufacturing parameters such as pressure, humidity and temperature.

SIMPLE TO USE

- Place Tervia Hub on top of your tool and plug-in the three vacuum lines

- Connect your PC or mobile device to the Tervia Hub Application

- Tervia Hub will locate leaks so you can quickly seal the bag

- You can run automatic Leak Rate Tests and obtain complete reports

For higher accuracy, you can plug 2 or more Tervia Hub to the same tool

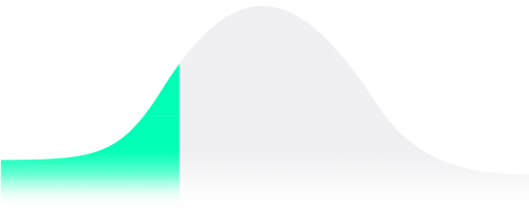

RESIN CURE MONITORING

Follow your process. Even on the go

Tervia Hub measures the resin cure in-situ and sends SMS/email alarms when part is fully cured or temperature threshold is reached

Tervia Hub measures the resin cure in-situ and sends SMS/email alarms when part is fully cured or temperature threshold is reached

progression

Visual cure progression

00:00:00

Remaining time

to fully cure

to fully cure

MOBILE APP

Tervia Hub supports LEAN Manufacturing by keeping track record of production:

- Vacuum pressure data

- Atmospheric pressure

- Preform moisture content

- Temperature variations

Available on